Concrete blocks are a staple of the construction industry. But producing a key ingredient of those blocks – cement – generates lots of carbon-dioxide emissions. What if you could make concrete products in a way that soaks up CO2, instead of releasing it into the atmosphere?

That’s the idea behind CarbiCrete, a Montreal-based cleantech company founded by a team of McGill University graduates that now employees 50 people.

Since its creation in 2016, the start-up’s breakthrough technology for manufacturing carbon-negative, cement-free blocks has won it a string of international honours. These include CarbiCrete having been twice named to the Global Cleantech 100, a list compiled annually by San Francisco-based research firm Cleantech Group as “a guide to the most innovative and promising companies poised to impact the market and the future of global industries in the next five to ten years.”

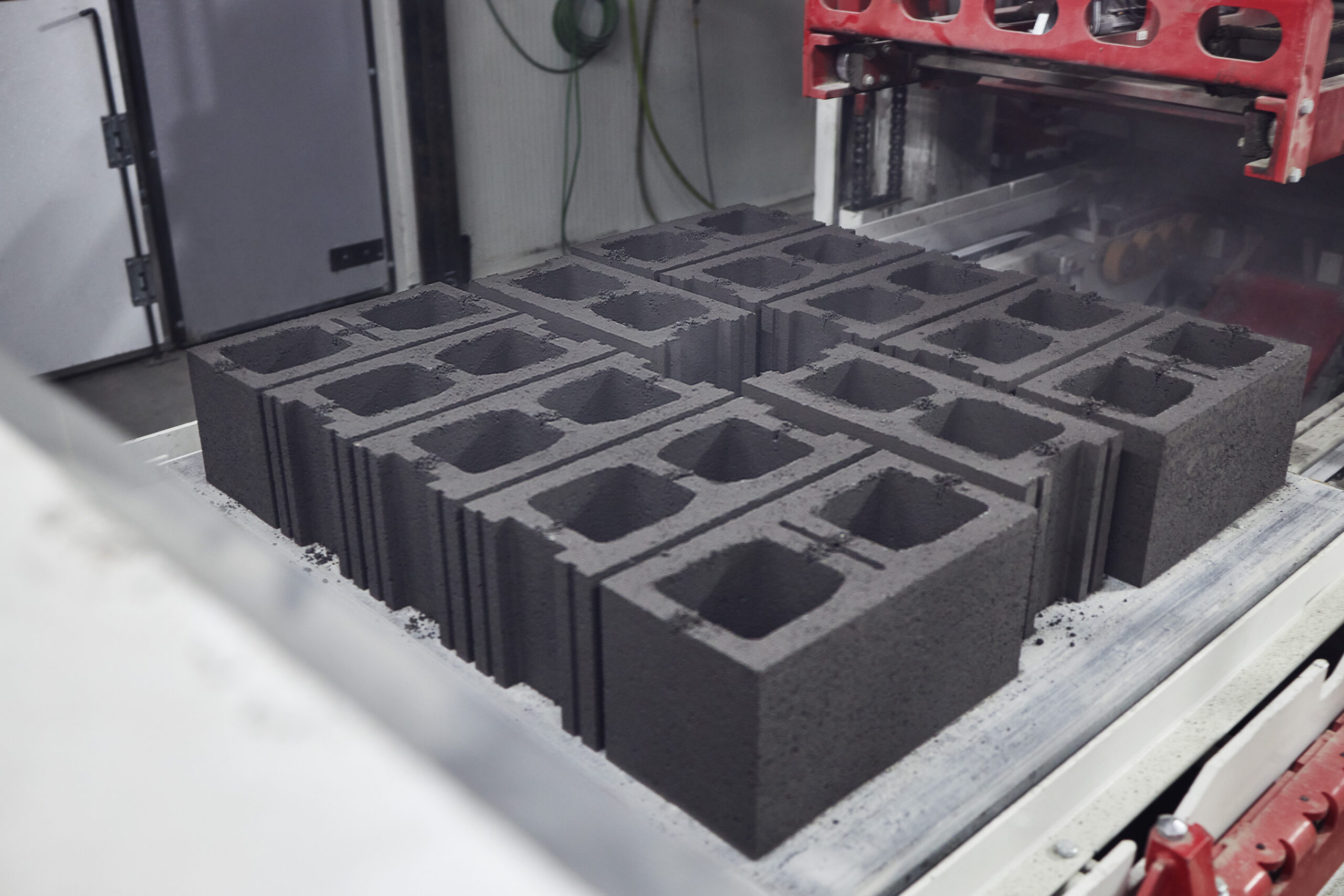

Today, CarbiCrete’s technology is being deployed by Patio Drummond, a leading North American manufacturer of concrete products.

Into production in Drummondville

A pilot project to produce concrete blocks at Patio Drummond’s plant in Drummondville using CarbiCrete’s technology began in early 2021. It was backed by $3.15 million in funding from the Québec government’s Technoclimat program, administered by the Quebec Ministry of Energy and Natural Resources, a $2.1 million grant from Sustainable Development Technology Canada, as well as by funding from other sources.

CarbiCrete’s technology “is perfectly aligned with our government’s vision of reducing greenhouse gas emissions and improving energy efficiency for a more prosperous Québec,” said Jonatan Julien, then-minister of Energy and Natural Resources, in announcing the Quebec government funding in 2020.

And now, CarbiCrete’s technology has been brought to market. Carbon-negative concrete blocks manufactured by Patio Drummond became available for purchase by consumers in September. Production is currently 2,400 blocks per day, but the companies recently announced plans to double that. The company calculates that for every 2,000 CarbiCrete blocks produced, a tonne of carbon is removed from the atmosphere, and more than three tonnes of emissions avoided.

CarbiCrete announced in December that Lafarge Canada would be processing steel slag for CarbiCrete at its St. Constant – Montreal East facility. Steel slag is a key ingredient in CarbiCrete’s formula and a byproduct of the steel-making process that is usually sent to the landfill.

Carbon-negative footprint

CarbiCrete’s technology, first developed in a McGill Engineering lab, uses the slag from steel factories to replace cement as a binding ingredient in precast concrete products. The process also injects CO2 into the fresh concrete to provide strength, while permanently sequestering CO2 within the resulting products.

As a result, CarbiCrete’s blocks have a carbon-negative footprint.

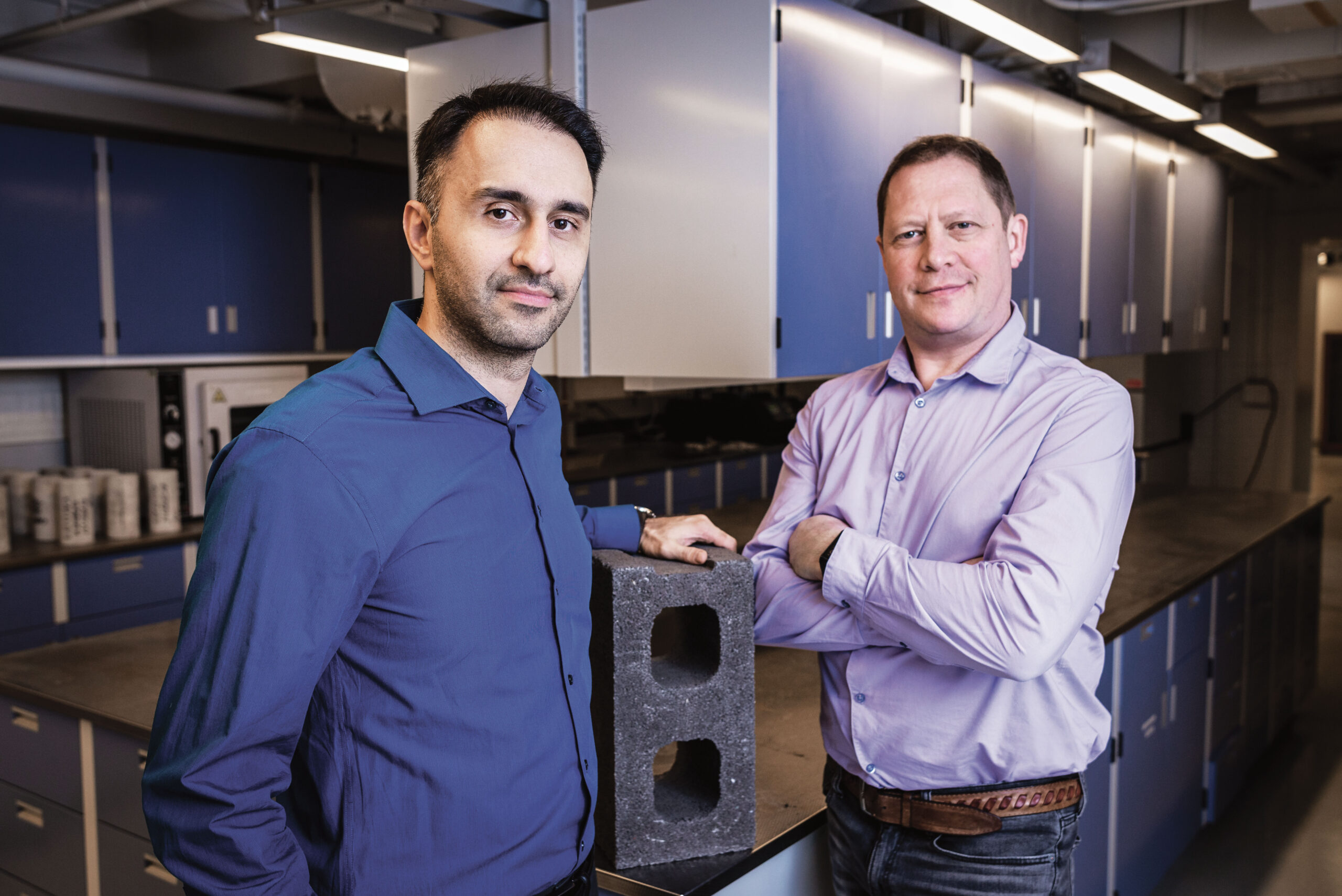

Mehrdad Mahoutian (PhD’14), CarbiCrete’s co-founder and Chief Technology Officer, developed the technology as a PhD student at McGill. Mahoutian teamed up with Chris Stern (BEng’94), a Montreal-based entrepreneur looking for promising green technologies, to co-found CarbiCrete in 2016, with Stern as chief executive officer and Mahoutian as chief technology officer.

McGill’s Dobson Centre played a key role

McGill’s Dobson Centre for Entrepreneurship helped CarbiCrete truly get off the ground.

“Participation in the Dobson Cup played a crucial role in the early development of CarbiCrete,” says chief marketing officer Yuri Mytko (BA’99), who has been with the company from the start. “It was the first opportunity we had to work together as a team on a project with a clear goal. It forced us to articulate what the company’s value proposition would be, and helped convince us that a successful business could be built around this McGill-born technological breakthrough.”

The company was among the winners in the “Innovation-Driven Enterprise” category of the 2016 McGill Dobson Cup competition.

From Quebec to the world

With blocks on the market in Quebec and a project underway with concrete masonry producer Canal Block in Port Colborne, Ontario, CarbiCrete is already making an impact in Canada. It’s also aiming to take its groundbreaking technology global by working with partners in the US and Europe and expanding its product range, says Mytko.

Stern stepped down as CEO in February 2024, but remains with the company as strategic adviser. The new CEO is Jacob Homiller, an executive with more than 25 years’ experience with global industrial companies. One of his focuses will be to help the company market its technology internationally.

In May 2023, CarbiCrete took an important step toward the use and certification of its technology in Europe with the signature of a pilot project agreement with French construction materials firm POINT.P, a subsidiary of Saint-Gobain.

And tapping into another revenue stream, the company is also selling carbon credits generated by the emissions reductions and carbon removals made possible by the CarbiCrete process.

Meanwhile, CarbiCrete’s made-in-Quebec technology is already providing a boost to Drummondville, while increasingly gaining global recognition.