By Chris Atack

MOTHER NATURE HAS BEEN DESIGNING DURABLE MATERIALS A LOT LONGER THAN HUMANS HAVE. The results are impressive — and instructive. Using an approach to materials architecture found in nature, associate professor of mechanical engineering professor François Barthelat and his colleagues have produced glass that is 200 times tougher than the ordinary substance.

Using a laser engraving technique, his team etched a complex pattern of microcracks on ordinary glass slides. The resulting substance was far tougher than ordinary, untreated glass. This microengraving technique has wide-reaching implications for strengthening not only glass but ceramics and other brittle substances.

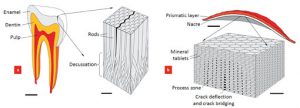

The idea behind Barthelat’s process for strengthening glass comes straight from nature. Ironically, the strength of some biological structures — teeth or mollusk shells for example — is the result of something which should logically make them weaker — webs of microcracks found throughout the structures. These microcracks direct, deflect and ultimately dissipate the forces they are subjected to, enabling teeth to chew without breaking and shells to protect their occupants.

In effect, this internal architecture acts a bit like a three-dimensional jigsaw puzzle, whose pieces become more tightly locked together as they are compressed.

“Some highly mineralized bio-structures have a complex internal architecture which channels propagating cracks into configurations that actually makes the structure stronger,” explains Barthelat. “These bio-structures exhibit a degree of stiffness, strength and toughness which even modern engineering materials cannot match. “

Making a material tougher by introducing weak interfaces may seem counterintuitive, but it appears to be a universal and powerful strategy in natural materials. “When it comes to designing tough, durable materials, we can learn a great deal from studying nature,” says Barthelat.