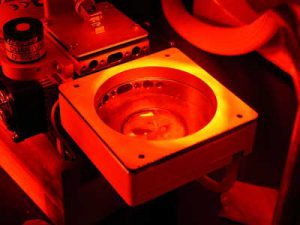

Bioresource Engineering lab testing greenhouse lighting technology

By Jim Hynes

Some greenhouse fruit and vegetable producers will soon be able to grow their produce more quickly and less expensively thanks to research into LED lighting conducted at McGill.

The Government of Canada and GE Canada announced last week that they have each invested $1.3 million in a research project with Les Serres St-Laurent (Savoura) and McGill to develop LED (Light Emitting Diode) lighting technology for commercial greenhouses to help improve growing efficiency while reducing business operational costs.

As northern greenhouses do not get enough sunlight in the winter, they need supplemental lighting to grow produce and other plants and flowers. The joint investment is expected to develop technologies that will enable Canadian greenhouse growers to become more profitable and competitive in the global marketplace. The anticipated benefits may include reduced energy consumption and year-round production, not to mention increased crop quality and yield. Federal funding for the project comes from the Developing Innovative Agri-Products (DIAP) initiative, which is delivered by the Growing Forward framework under the Agri-Innovations program, a $158 million five-year program to support industry-led science and technology projects.

Savoura, one of the largest greenhouse tomato growers under supplemental lighting in the world, will receive trial testing of GE’s LED lighting fixtures to help increase energy efficiency and lower production costs. Since the company has the technical expertise of growing tomatoes under artificial light, they have provided leadership, expertise and technical support for planning the experiments.

GE Lighting Solutions selected Mark Lefsrud, an assistant professor in McGill’s department of Bioresource Engineering, to conduct research on plant-specific Photo-synthetic Active Radiation (PAR) curves (the specific light wavelength plants require for optimum growth) that plays a key role in the advancement of this significant new lighting option for the horticultural industry. Although the funding for the project was only recently announced, the research actually got underway in April 2010 on tomato seedlings in Lefsrud’s lab on the Macdonald Campus.

LED lights emit specific colours or wavelengths of light – red, green, blue, orange, you name it. The goal, Lefsrud said, is finding the right wavelengths.

“LEDs are very narrow in their spectrum, so when they are red they are just red,” he said. “We’re trying to determine which wavelengths are the best, or what colours are the best to allow our plants to grow. So we’re doing specific wavelength testing. Our goal is to determine what wavelengths and what ratios of colour ranges work best.”

Lefsrud conducted the testing with his students Most Tahera Naznin (PDF), Michael Schwalb (MSc), Julie Gagne (MSc), and undergraduates Blake Bissonnette and Alejandro Jaul.

“We went out and purchased 14 different LED arrays, from five to 60 lights, but they’re all emitting the exact same colour or wavelength of light, and we’re then shining that on the seedlings,” Lefsrud explained. “The challenge is that most of the LEDs that we are used to seeing are very dim. And when you are growing plants you want them to be at full sunlight. One LED can produce about one-tenth to one-fifth full sunlight, so if we group a bunch of them together, of the right wavelength, we should be able to get up to full sunlight.”

Lefsrud said he expects greenhouse energy savings in the 25 to 40 per cent range, with 50 per cent a possibly as the efficiency of the LEDs continues to improve. And there are other benefits as well.

“The heat load of the LEDs is almost none existent. You can put the plant right up next to it,” Lefsrud said. “With standard lights you have to keep them at least three feet away or you’ll start burning the plants.”

Today it’s the tomato, tomorrow, who knows? Lefsrud and his team are already conducting tests on lettuce and petunias. The long-term goal is to one day grow just about anything indoors under artificial lighting.