In the fall of 2019, McGill’s physics and chemistry departments were faced with a crisis.

In just over a year, the cost of helium had increased fivefold, said Dr. Tara Sprules, QANUC Nuclear Magnetic Resonance (NMR) facility manager.

“For us that just meant we had to keep finding more money to pay for the helium,” said Sprules. “In the physics department it meant that they had to change some of the research that they did because they just couldn’t afford to do that type of research anymore.”

That is because helium is the only element that can be chilled down to the ultracold temperatures needed for superconducting magnets, which are essential to chemistry and physics research, explained Robin Stein, NMR Facility Manager with the Department of Chemistry.

Helium cools the magnets down to 4 Kelvin, or -269.1°C, the temperature at which they need to be to maintain their charge. McGill’s NMR facilities, which rely on these superconducting magnets, are used by about 30 McGill research groups and nearly 20 external groups annually, in addition to undergraduate and graduate teaching.

Reducing helium reliance

At McGill, the NMR facilities in Otto Maass and Pulp and Paper use about 3,000 litres of liquid helium annually. Because helium is so light, that amounts to 60,000 litres evaporated into the atmosphere – lost forever – over the 20-year lifespan of the magnets. Even further, approximately 150 metric tonnes of CO2 is emitted during the extraction and shipment of that amount of helium, about the same amount as 100 round trip flights between Montreal and Los Angeles.

But with a proper recycling system in place, 90 per cent of helium can be recovered, reducing the facilities’ reliance on new helium to a bare minimum.

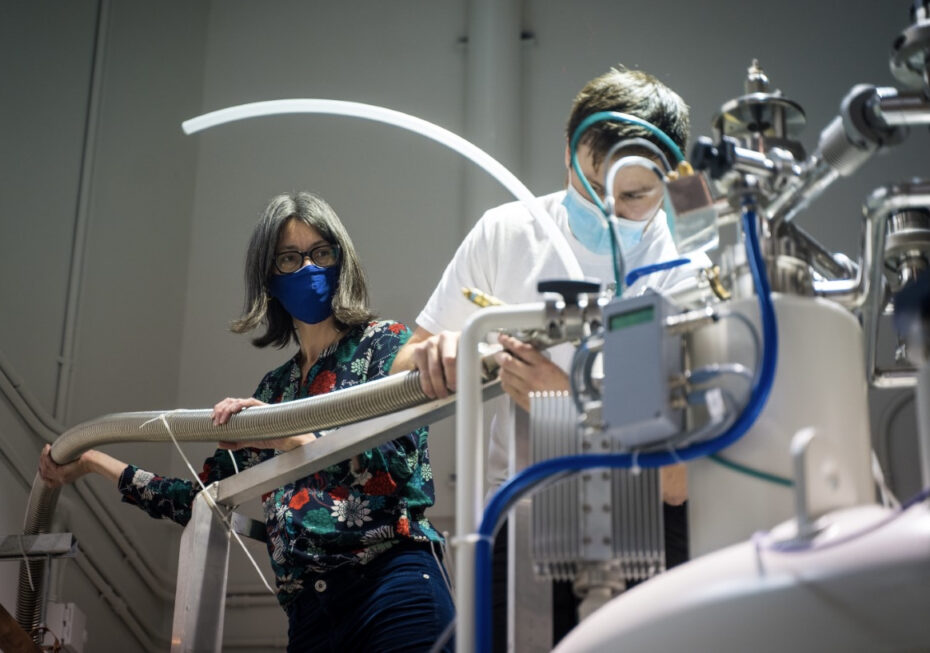

That is the goal for the Helium Recovery project, lead by Stein and Sprules alongside the Department of Chemistry’s Rick Rossi, Weihua Wang, Jean-Marc Gauthier and Jean-Phillipe Guay, implemented with the help of the Facilities teams from Otto Maass and Pulp and Paper.

Their project is supported in part by the Sustainability Projects Fund (SPF) Big Wave stream, which funds large-scale, transformative projects that have a long-lasting impact on McGill’s campuses. Professors Dmitrii Perepichka, Chair of the Chemistry Department; Tony Mittermaier, Associate Dean (Student Affairs); and Youla Tsantrizos also helped push the project forward by identifying other sources of funding.

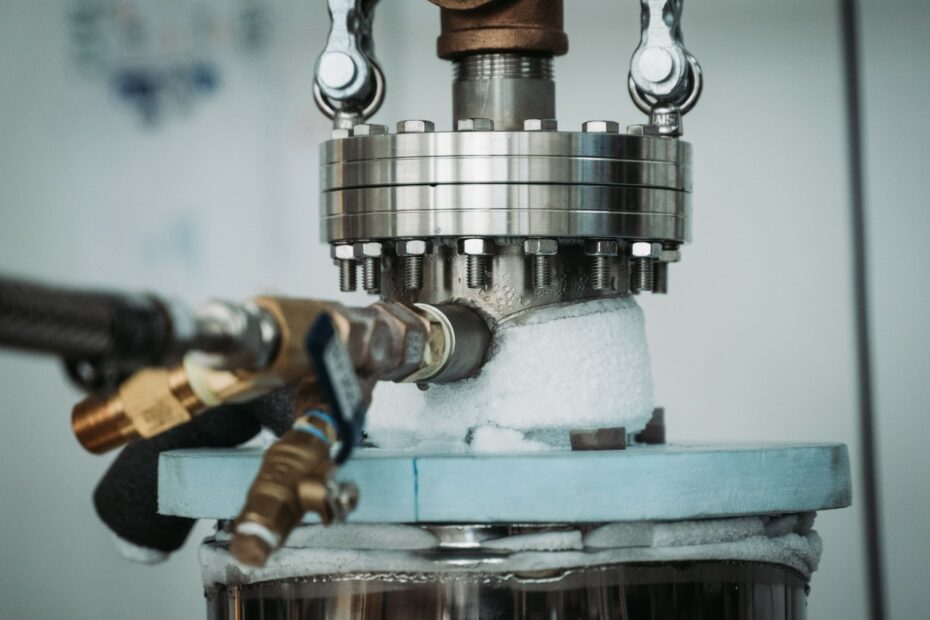

The system, which costs almost $400,000 to install, works by collecting the evaporated helium as it is used and passing it through a compressor, which pressurizes the helium so that it can be stored in compressed gas cylinders. When liquid is required, the gaseous helium is run through a purifier to remove any contaminants before a coldhead expands and compresses the gas, resulting in the removal of heat, turning the helium back into its liquid state. It is this process that chills the helium down to the extremely cold temperatures required by the NMR facilities, ready for reuse.

Recycling helium to avoid “creating new issues”

While the price has stabilized since the “crisis point” of fall 2019, helium is a byproduct of natural gas extraction, so “when natural gas usage goes down, like in recessions, the price of helium tends to go up,” said Stein.

Beyond the economic volatility of being tied to natural gas extraction, sourcing helium often comes at the cost of natural landscapes and biodiversity.

“Some of the other sources [of helium], like any sort of rare mineral, tend to be found in interesting geologic formations, which unfortunately also are often found in fairly pristine natural areas,” said Sprules.

“To construct a plant there to extract that helium, you’re going to be disturbing a nice natural area and, even if you’re not taking natural gas out, you’re disturbing the environment, tracking things along the way, changing the landscape,” she said. “It is disrupting the environment and creating new issues.”

And for as long as helium is required to maintain the ultracold conditions needed for superconducting magnets, Sprules and Stein agree that recycling helium is the direction McGill’s NMR facilities need to move in.

“It’s now clear we’re going to need to be able to go forward with these types of instruments,” Sprules said of the recycling system.

The savings? With the anticipated decrease in new helium needed for the Otto Maass and Pulp and Paper NMR facilities, the team believes they will reduce spending by about $1.3 million over the 20-year lifespan of their magnets.

McGill’s Sustainability Projects Fund (SPF) is the largest fund of its kind in Canada with a mandate to build a culture of sustainability on McGill campuses through the development and seed-funding of interdisciplinary projects. You can learn more about the Helium Recovery System by visiting the team’s SPF project page.

Fourth paragraph missing a that.

Thanks for the eagle eye, Chris! The text has been fixed.